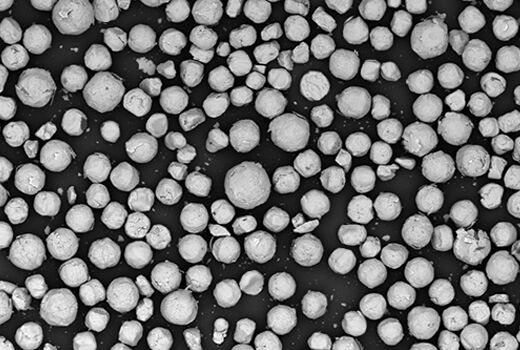

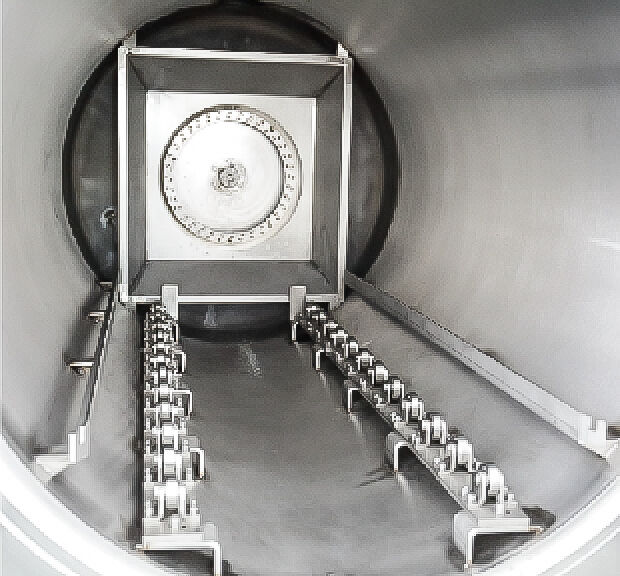

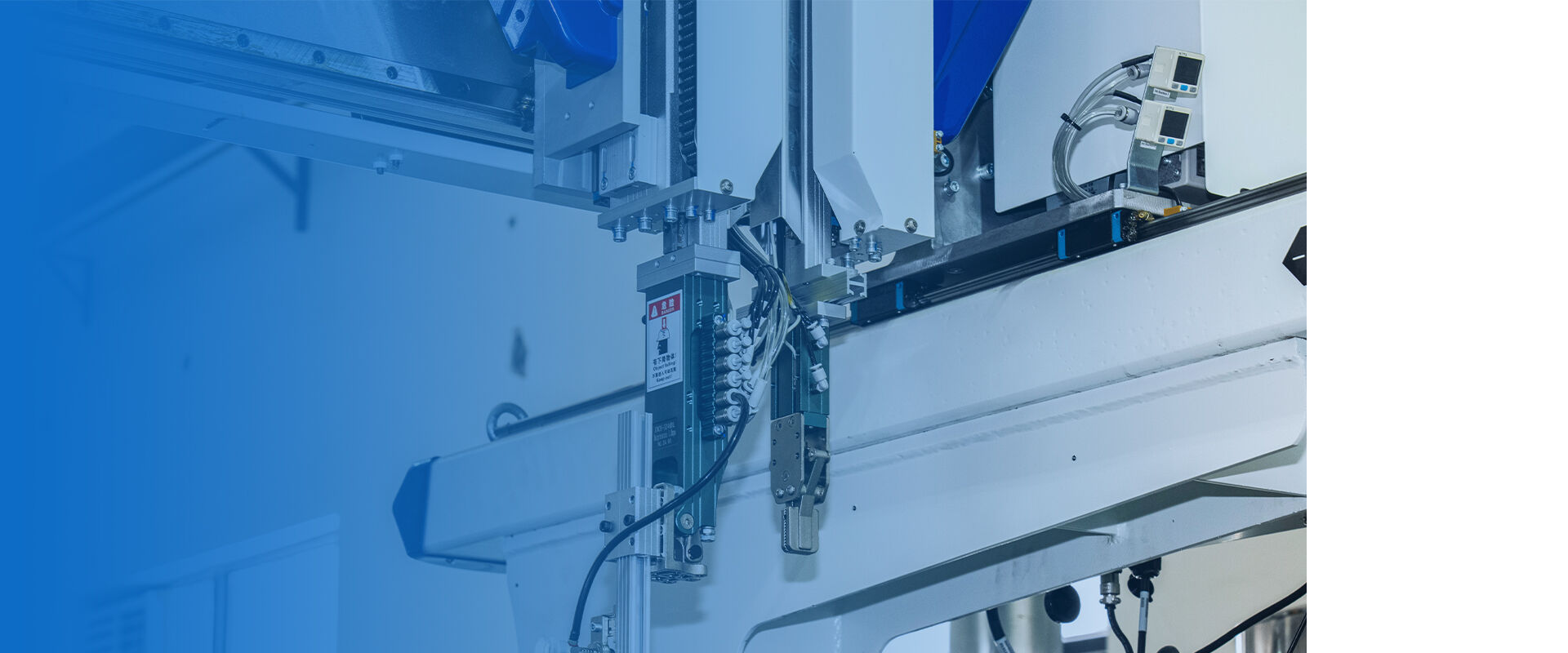

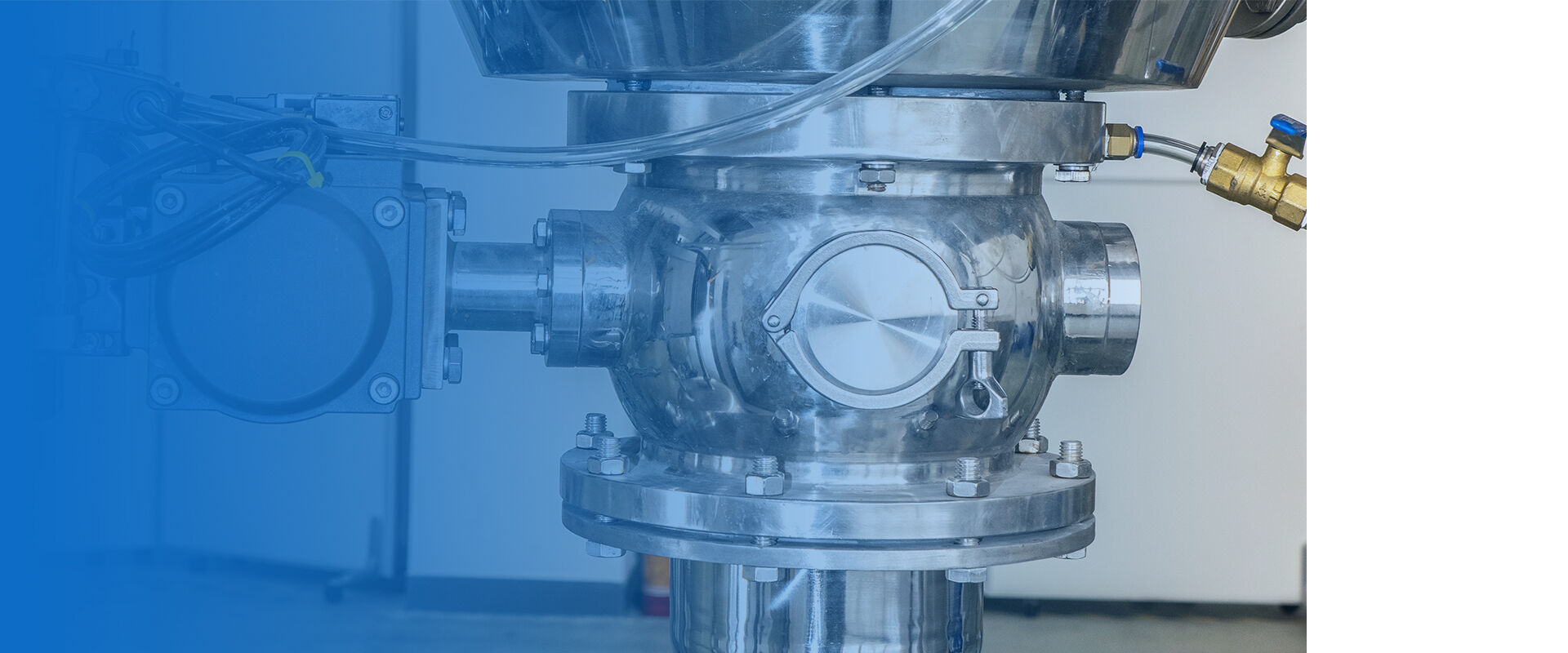

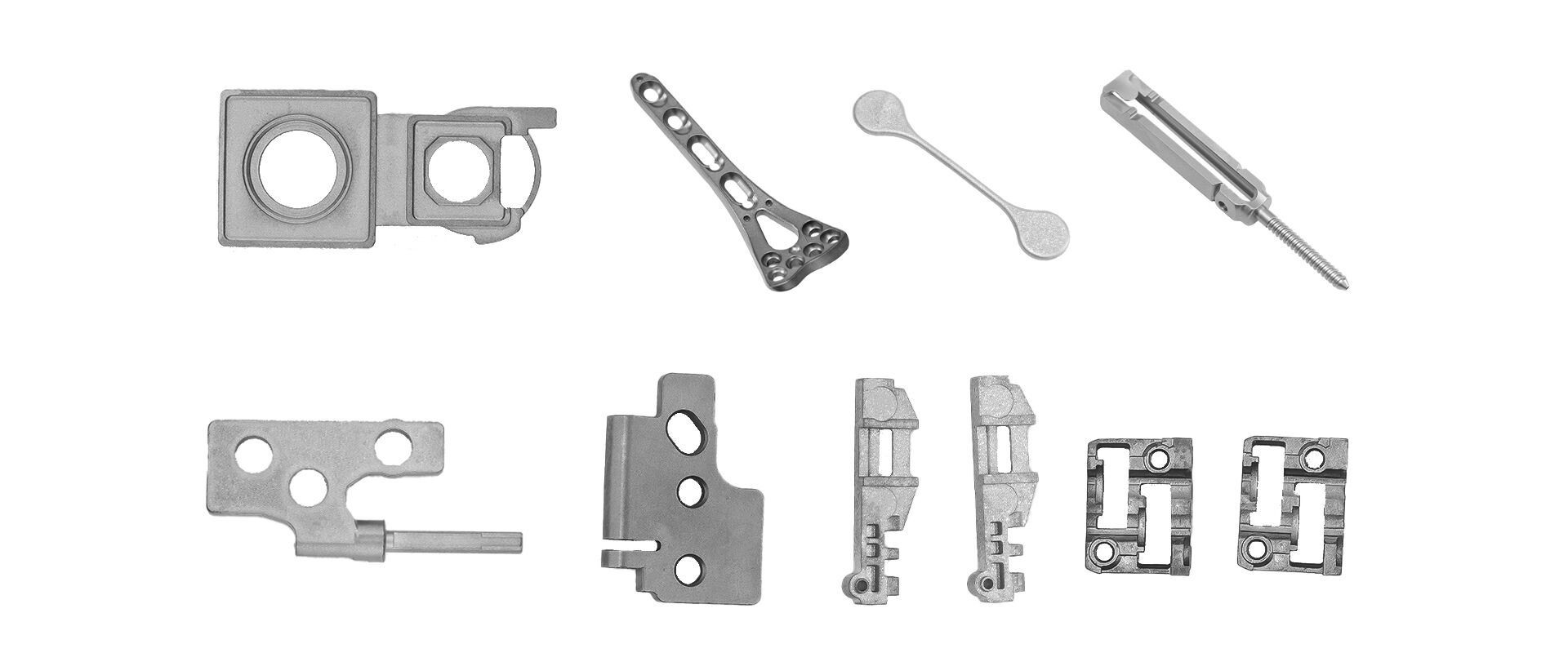

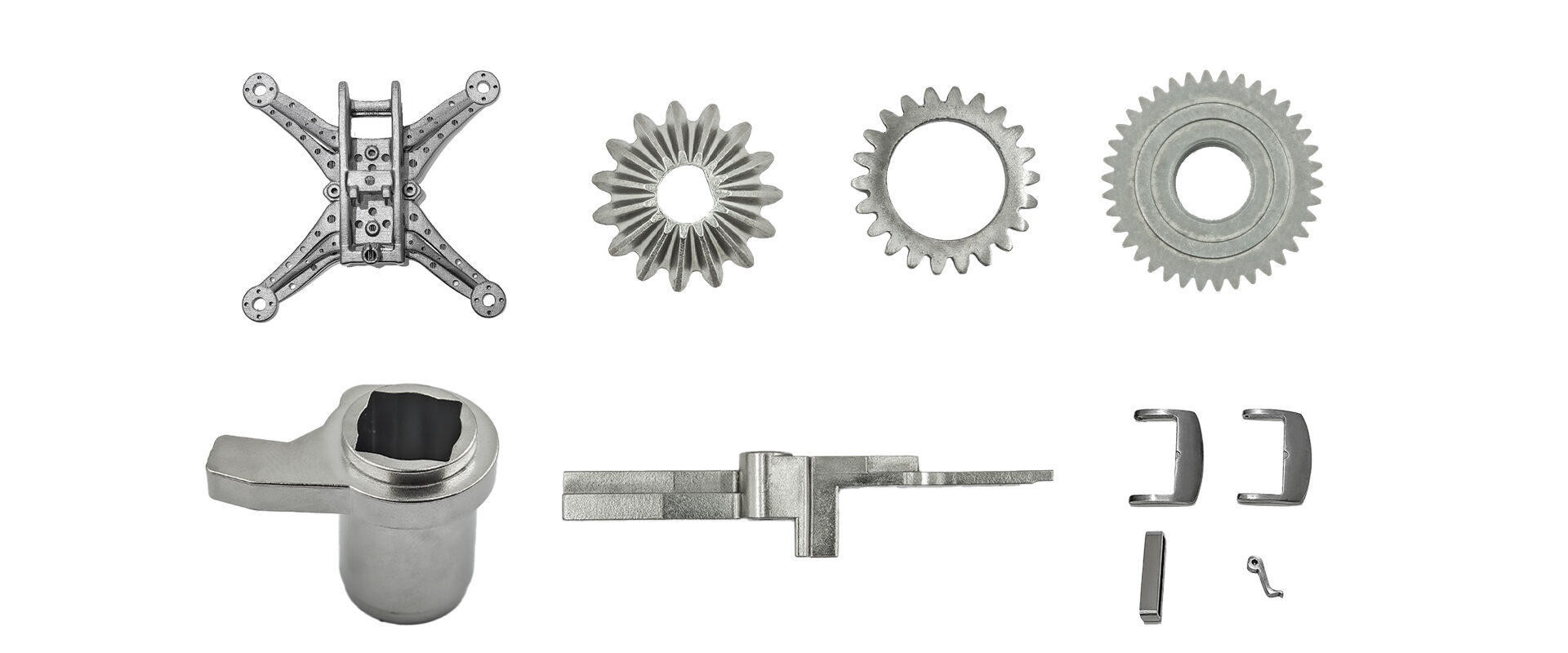

For specific application requirements, we provide clients with comprehensive services encompassing custom material design, powder prototyping, and molded component manufacturing. 3D printing technology enables rapid response for small-batch customized production, while metal powder MIM (Metal Injection Molding) technology delivers the most cost-effective solution for complex titanium alloy components.