Our company was founded in October 2023 by Dr. Haoyin Zhang, who was mentored by Professor Thomas Ebel, President of the European Powder Metallurgy Association (EPMA). Dr. Zhang’s academic and research expertise focuses on titanium alloys, additive manufacturing, and metal injection molding (MIM). The company’s core engineering team consists of ten senior engineers, all of whom have extensive professional experience in manufacturing roles at publicly listed companies.

• Secured seed-round financing

• Selected for the Xiangshan Elite Program

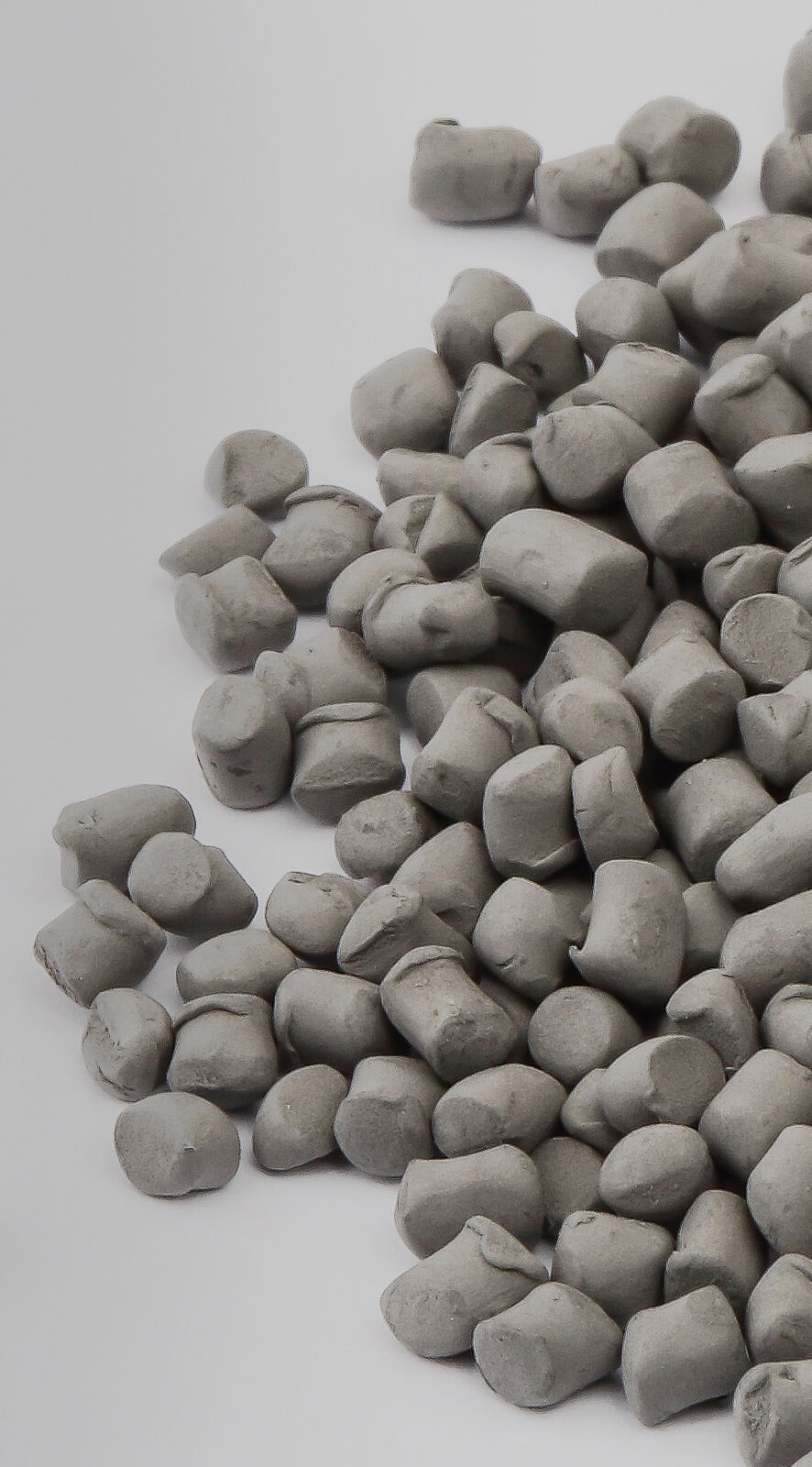

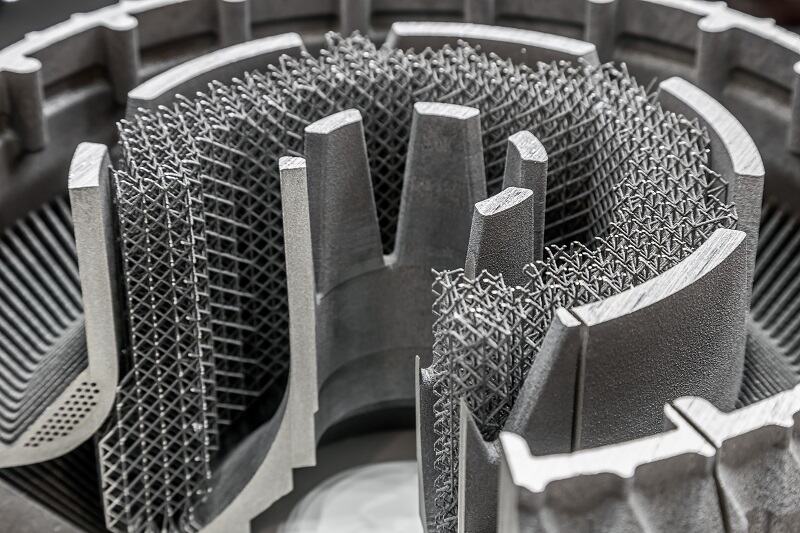

• At the beginning of the year, the DH-S® process entered mass-production ramp-up

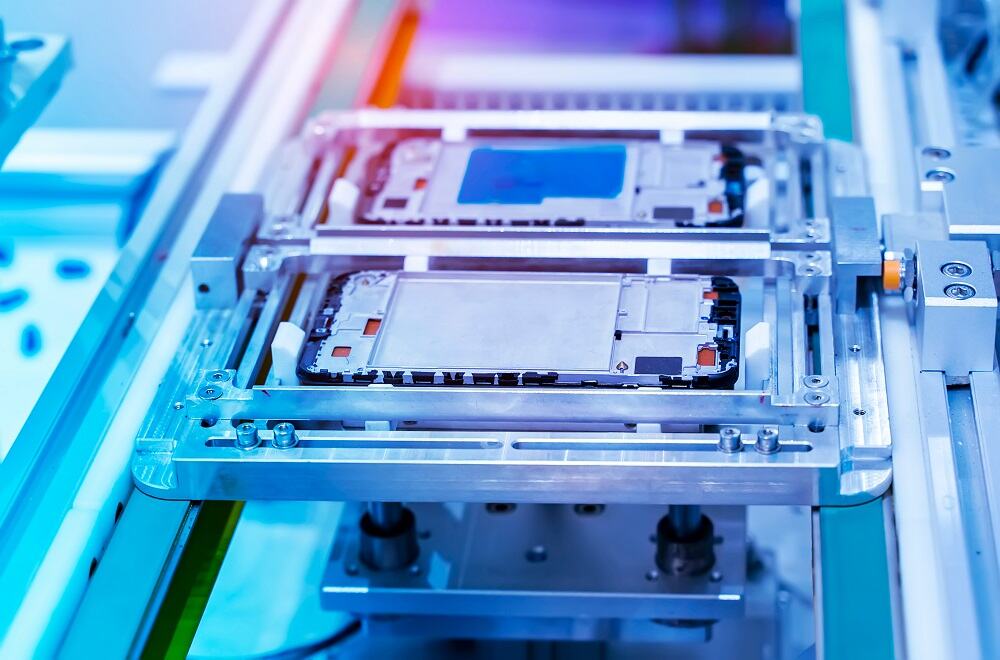

• Signed NDAs with multiple leading consumer electronics companies domestically and internationally

• Product line validation / aduit in progress

• Powder and component production lines have reached full mass-production readiness

• Secured orders exceeding RMB 10 million in a single contract

• Obtained angel-round investment

• Expansion of powder and component production lines

• Entered the supplier systems of multiple leading customers

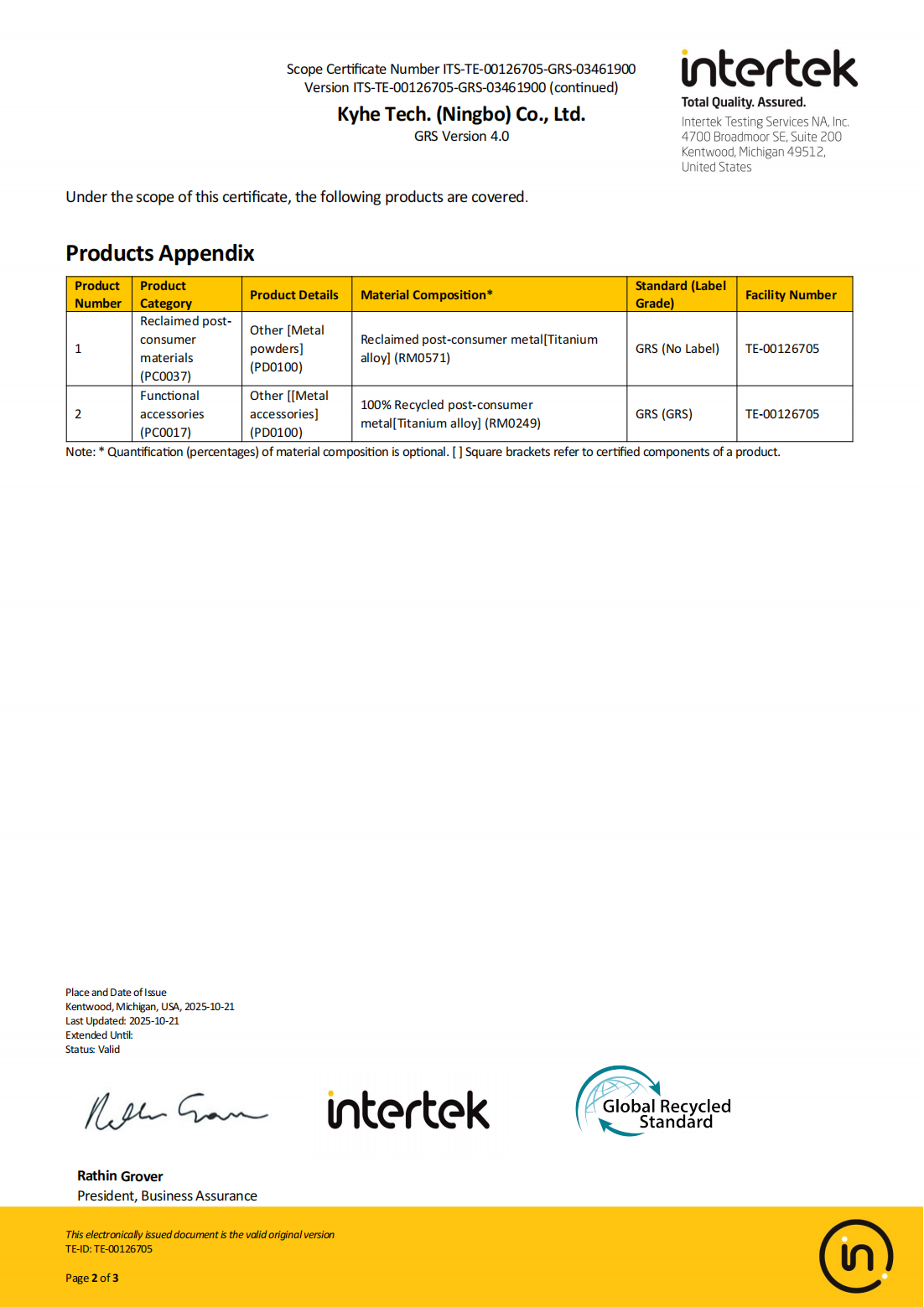

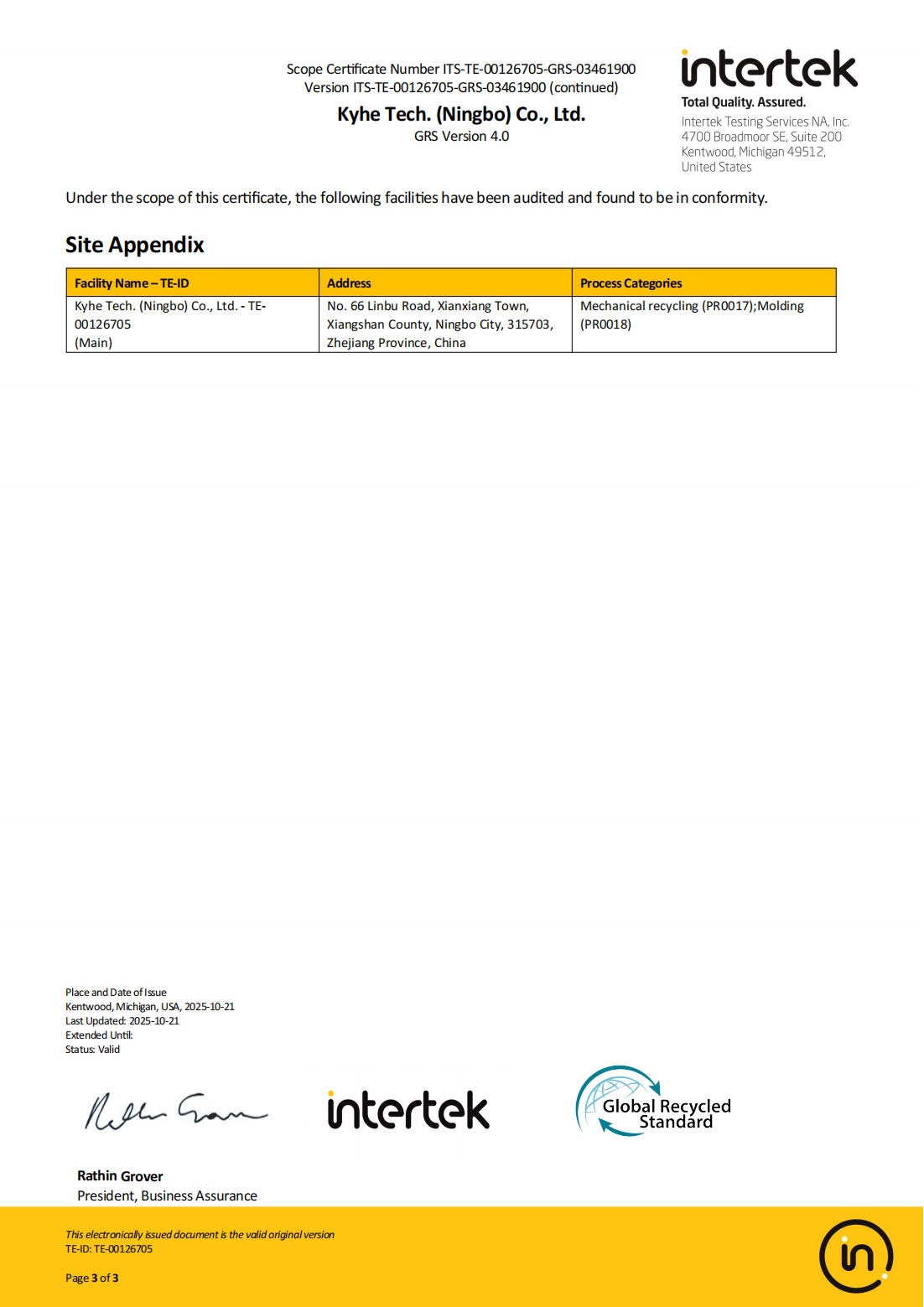

• Achieved GRS certification for 100% titanium alloy recycling

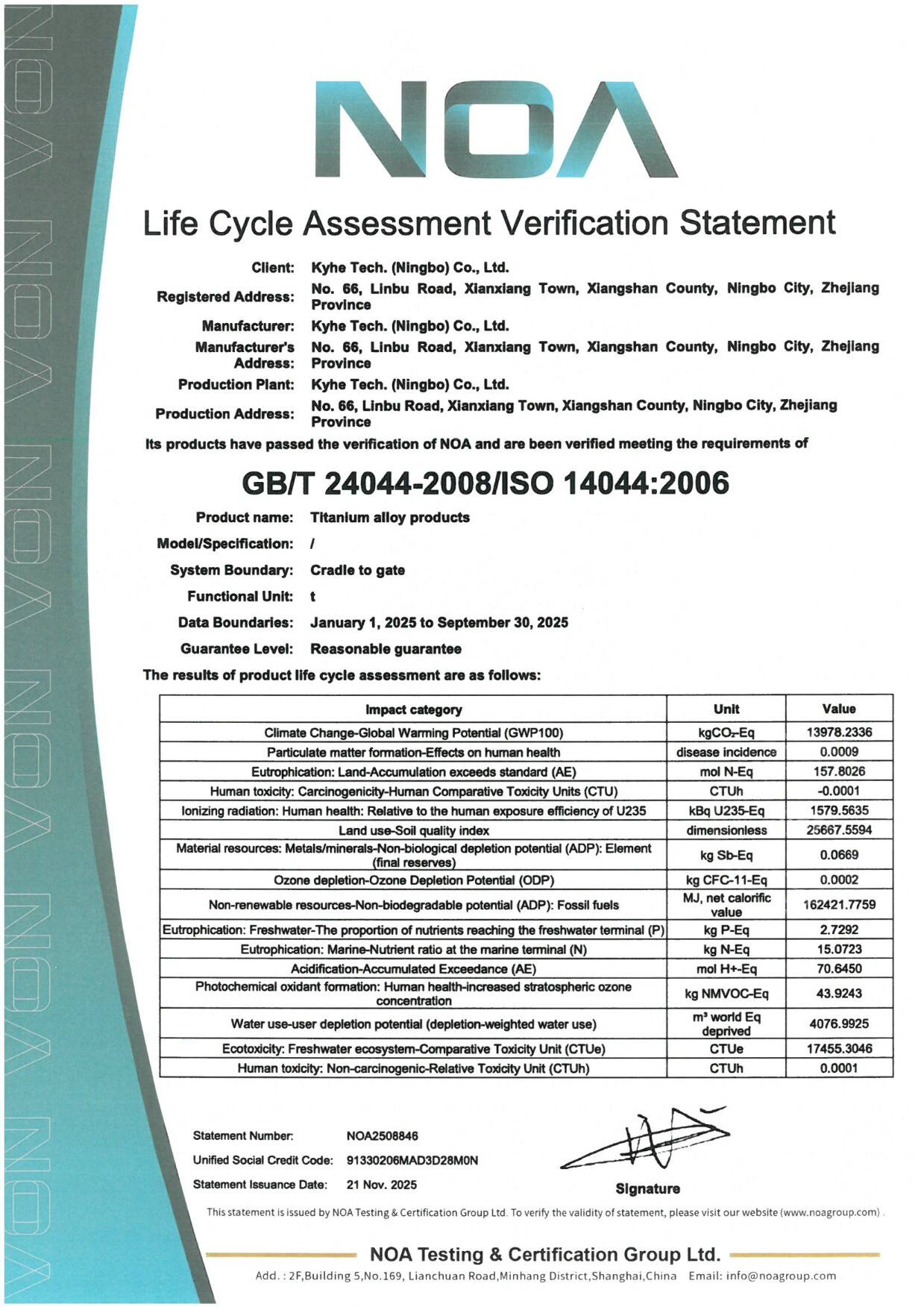

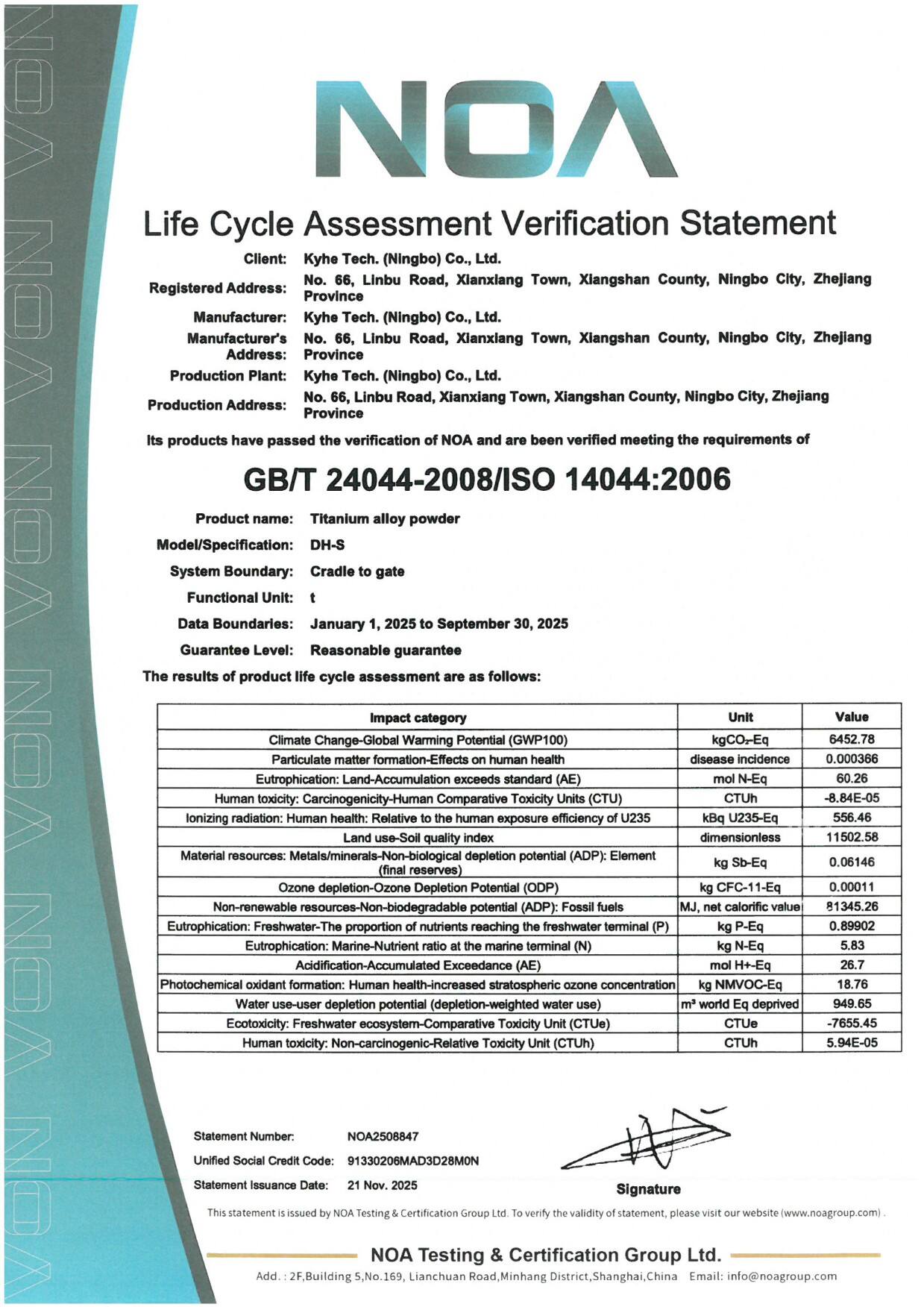

• Obtained LCA certification, advancing ESG practices