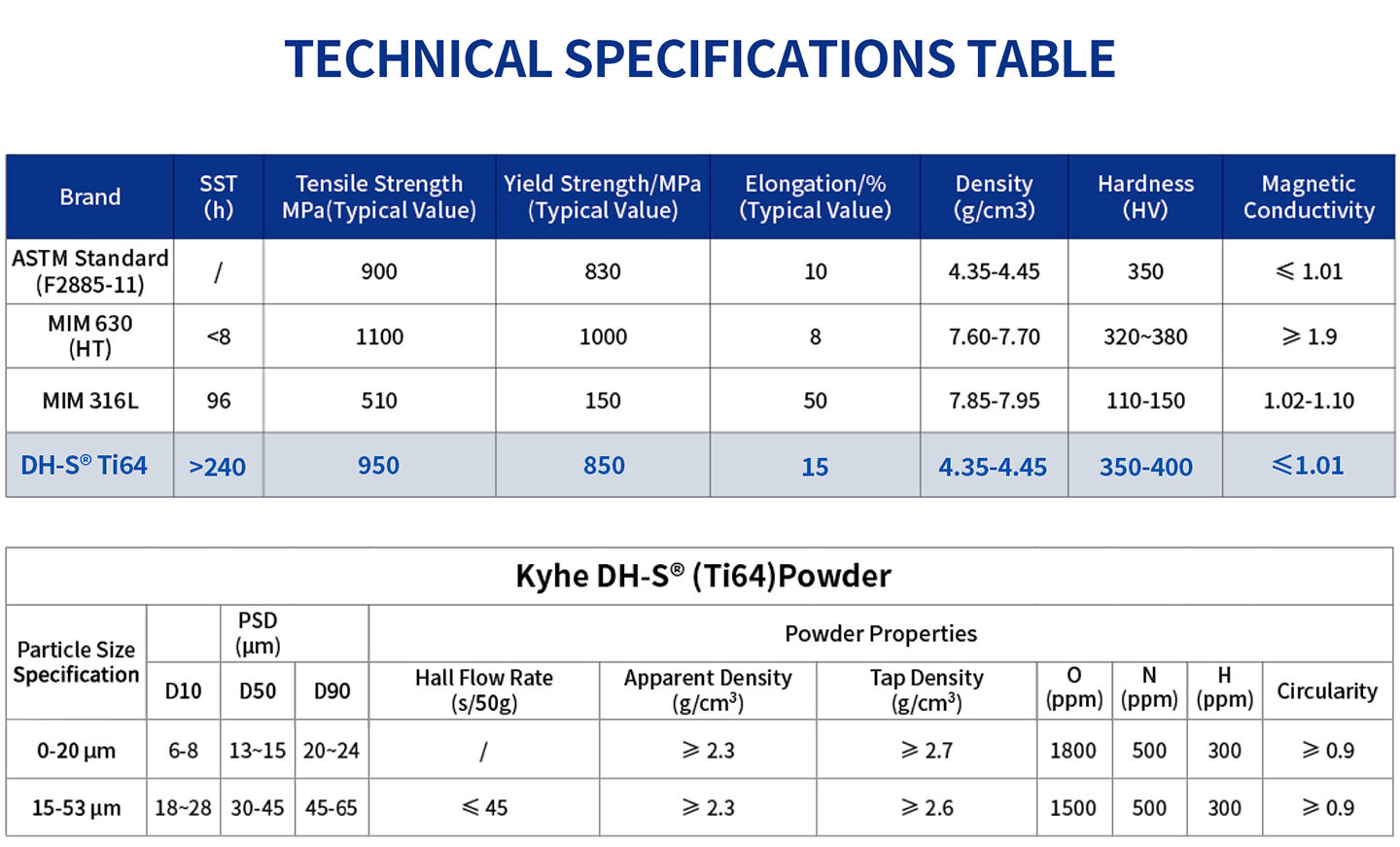

Titanium Alloy Powder - 0~20μm:

Its ultra-fine particle size and high specific surface area enable homogeneous mixing with binders, forming high-uniformity feedstock for Metal Injection Molding (MIM).

This ensures:

• Complete filling of intricate mold cavities during injection

• Higher sintered density post-debinding

• Meeting MIM's core demands for feedstock consistency,molding precision, and sintered density.

Titanium Alloy Powder - 15~53μm :

Optimal particle size distribution and superior flowability.

This ensures:

• Compatible with a wide range of 3D printing technologies, including SLM and EBM

• Ensures complete melting with no fine-powder agglomeration or partial-melt defects

• Fully meets the requirements of 3D printing processes in terms of powder-bed uniformity and process stability

KYHE TECH. leverages its proprietary DH-S® patented process for recycled titanium alloy powder. This process achieves a single-batch yield rate of 95%, reduces costs by 60% compared to traditional EIGA methods, and delivers excellent powder performance.

Furthermore, as the first domestic company to obtain GRS certification for this powder, KYHE TECH. utilizes over 95% of titanium scrap and reduces carbon emissions by 50%.

Its Ningbo base provides stable production capacity and a comprehensive inspection system. The business covers the entire production chain, offers versatile solutions adaptable to various fields, and supports customization, establishing a significant competitive advantage.

Medical Industry

Medical Industry

The medical sector requires the mass production of micro-scale titanium alloy components featuring high precision and extremely low rejection rates for use inside the human body—such as parts for minimally invasive surgical instruments and implantable auxiliary devices.

Industrial Intelligent Equipment Sector

Industrial Intelligent Equipment Sector

Requires high-stability, wear-resistant titanium alloy components (e.g., robotic arm joints, sensor mounts for smart inspection systems, AGV drive units).

Automotive & Motorcycle Industries

Automotive & Motorcycle Industries

Demand low-density, high-strength titanium alloy parts (e.g., engine fasteners, lightweight chassis structural components).

Consumable Electronics

Consumable Electronics

Seeking rare metals to enhance brand value, as well as cost-effective materials capable of replacing existing solutions—for example, premium keyboard housings and metal fasteners used in smart devices.

Precision Instruments Sector

Precision Instruments Sector

Requires high-precision, low-deformation titanium alloy hardware components (e.g., retention screws, calibration knobs).