The world of advanced manufacturing is evolving rapidly, and 3D printing with titanium alloys is at the forefront of this transformation. Titanium’s legendary strength-to-weight ratio, corrosion resistance, and biocompatibility make it ideal for high-performance applications—from aerospace to medical implants. Yet for years, high costs and technical barriers limited its adoption. Kyhe Tech is changing that narrative with its groundbreaking DH-S® 100% recycled titanium powder, turning industry challenges into opportunities.

Why Titanium 3D Printing?

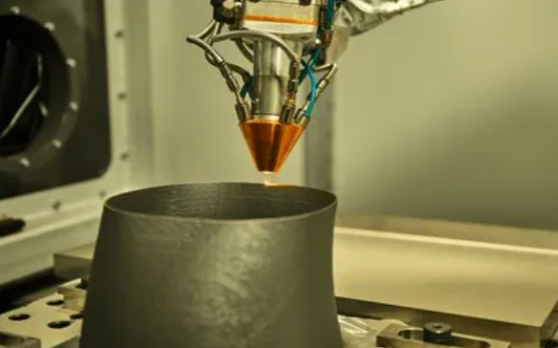

Traditional manufacturing often struggles with titanium’s complexity. Machining creates up to 90% material waste, while conventional powder production relies on energy-intensive processes. 3D printing solves these issues by enabling precise, near-net-shape fabrication of intricate designs—but only if the powder is affordable, sustainable, and high-performing. That’s where Kyhe Tech steps in.

Kyhe Tech’s DH-S®: The Game-Changer for Additive Manufacturing

Cost Efficiency Meets Circular Economy

Kyhe Tech’s proprietary DH-S® technology transforms recycled titanium sources—CNC scrap, coarse powder, and more—into premium 3D printing powder. By sidestepping virgin material costs, Kyhe offers titanium powder at near-stainless-steel pricing. This democratizes access to titanium, allowing industries like consumer electronics and healthcare to adopt it at scale.

Engineered for Perfection

Unlike traditional powders with fixed particle distributions, DH-S® powder is precision-tailored for 3D printing:

Optimal Particle Size (15-53μm): Ensures smooth flow and dense packing in SLM (Selective Laser Melting) printers.

High Sphericity (≥0.9): Reduces voids and boosts mechanical integrity.

Low Oxygen Content (1,500–1,800 ppm): Maintains strength and corrosion resistance post-printing.

Performance Without Compromise

Kyhe’s DH-S® Ti6AL4V powder exceeds industry standards:

Tensile Strength:1000 MPa | Yield Strength: 850 MPa | Elongation:>12%

Corrosion Resistance: >240 hours in SST testing—ideal for implants and harsh environments.

Sustainability Built In

Kyhe doesn’t just talk about green manufacturing; it proves it. Every batch of DH-S® powder is:

GRS 4.0 Certified: 100% traceable recycled content.

Produced Responsibly: Intertek-audited facilities ensure ethical sourcing and low-carbon processes.

Scalable: With a 500-ton annual capacity, Kyhe meets global demand sustainably.

Real-World Impact

When Apple chose 100% recycled titanium for its Apple Watch Ultra 3 mid-frame, it validated Kyhe’s vision. But the applications go further:

Medical: Patient-specific implants with biocompatible titanium.

Aerospace: Lightweight, high-strength components that cut fuel costs.

Automotive: Durable parts that reduce vehicle weight and emissions.

The Kyhe’sAdvantage: More Than Powder

Kyhe Tech.offers end-to-end support—from custom alloy development to small-batch validation—accelerating clients’ R&D cycles. This “innovation partnership” model sets Kyhe apart in the 3D printing ecosystem.

Conclusion: Leading the Next Industrial Revolution

As industries embrace sustainability and precision manufacturing, Kyhe Tech’s recycled titanium powder isn’t just keeping pace—it’s defining the future. By merging affordability, performance, and eco-certification, Kyhe empowers manufacturers to build lighter, stronger, and greener.