In the consumer electronics and advanced manufacturing sectors, every technological iteration by Apple sends ripples through the supply chain. On September 10, 2025, Apple's latest release, the Apple Watch Ultra 3, featured a 100% recycled 3D-printed titanium alloy mid-frame, igniting market excitement with its dual appeal of "eco-friendliness + innovation." This move has positioned "recycled titanium alloy materials" and "3D printing technology integration" as the industry's new frontier.

KyheTechnology has long established a competitive edge with its proprietary advanced titanium alloy powder preparation technology: DH-S® (Dehydrogenation Spheroidal). Through its series of eco-friendly recycled titanium alloy powders and end-to-end solutions,Kyheserves the 3C consumer electronics, medical, and automotive industries, aligning with ESG principles. It offers a "low-cost + high sustainability" option for MIM (Metal Injection Molding) and 3D printing manufacturing.

Apple's "100% Recycled Titanium Alloy" Benchmark

Sustainable Manufacturing Becomes an Industry Imperative

Apple's choice of 100% recycled titanium alloy for its watch mid-frame is not merely a technical experiment but a precise response to the global manufacturing trend toward sustainability. Titanium alloy, known for its lightweight, high strength, and corrosion resistance, has long been an ideal material for high-end manufacturing. However, traditional titanium production suffers from high energy consumption, high costs, and resource waste. The combination of "recycling + 3D printing" addresses raw material circularity while enabling efficient formation of complex structures through additive manufacturing—perfectly aligning with Apple's carbon neutrality strategy by 2030 and its lightweight product requirements.

From this, it’s clear that the application and promotion of new materials in traditional manufacturing now have concrete solutions and directions. For conventional titanium alloys, DH-S® resolves a series of pain points and challenges while meeting clients' carbon neutrality and lightweight needs through additive manufacturing.

Thus, future high-end manufacturing must not only meet performance requirements but also demonstrate clear sustainability credentials.KyheTechnology has obtained the internationally recognized GLOBAL RECYCLED STANDARD 4.0 (GRS 4.0) certification (Certificate No. ITS-TE-00126705-GRS-02566800). Its flagship product, DH-S® eco-friendly recycled titanium alloy powder, is explicitly labeled as "100% Recycled Post-Consumer Metal (Titanium Alloy)," ensuring traceability and full recyclability from the raw material source. This aligns seamlessly with Apple's environmental ethos, makingKyhea premium partner for high-end consumer electronics demand.

KyheTech's DH-S® Titanium Powder

Solving the Pain Points of Titanium Alloy Powder Raw Materials

As a tech company specializing in green titanium alloy powders, Kyhe boasts core strength in its self-developed its self-developed DH-S® physical powder spheroidization technology. This innovation not only eliminates the high energy consumption and pollution of traditional titanium powder production but also tackles two critical industry challenges: cost and capacity.

1. Cost Revolution: Near-Stainless Steel Pricing, Breaking Titanium Alloy Barriers

Historically, "high cost" has been the primary obstacle to widespread titanium alloy adoption.Kyhe's exclusive DH-S® technology enables the production of usable titanium alloy powder from multiple raw material sources, such as coarse powder above 53 microns, CNC titanium scrap, and sponge titanium. By avoiding raw material bottlenecks,Kyheunlocks cost efficiencies, delivering "high quality at low prices." This cost reduction means products previously unable to use titanium due to budget constraints can now benefit from its lightweight and high-strength advantages, democratizing access to titanium alloy. For instance, usingKyhe's recycled titanium powder for 3D printing or MIM manufacturing of Apple's watch mid-frame meets performance requirements while controlling costs, offering consumer electronics manufacturers a new path to "cost efficiency."

2. Adjustable Particle Size Range, Capacity Up to 500 Tons

Traditional EIGA processes produce powder with a particle size distribution following a normal curve, where only 10% of each batch falls within the 0-20 micron range (suitable for MIM) and about 40% within 15-53 microns (ideal for 3D printing). In contrast, DH-S® technology shatters these limitations. It allows adjustable particle size distribution per batch, with a 92% yield rate, ensuring 100% compliance with client specifications. Additionally,Kyheoperates a 9,500-square-meter independent facility and has completed two funding rounds. Based on current client orders, it is rapidly expanding production, targeting an annual output of 500 tons.

3. Meeting High-End Manufacturing Needs: Compatible with MIM and 3D Printing

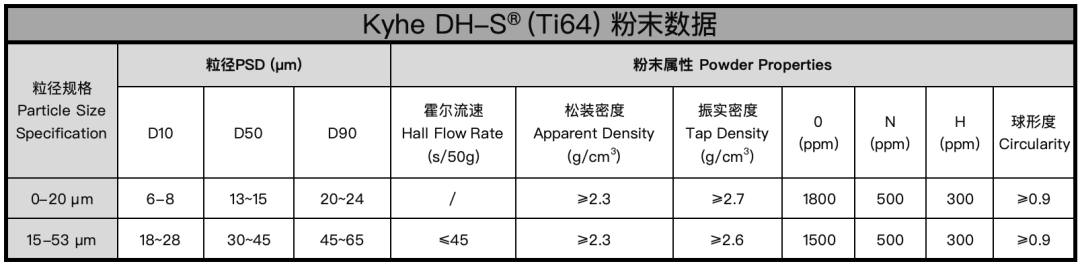

Despite cost reductions,Kyhe's DH-S® titanium powder maintains uncompromised performance. According to technical specifications, its DH-S® Ti64 (Ti6Al4V) powder excels in key metrics:

Mechanical Properties: Tensile strength of 950 MPa, yield strength of 850 MPa, elongation of 15%, surpassing ASTM F2885-11 standards. Its corrosion resistance (SST test >240 hours) makes it ideal for demanding applications like consumer electronics and medical implants.

Powder Characteristics: Available in 0-20μm, 15-53μm, and other particle sizes, with a Hall flow rate of 20-50s/50g, tap density ≥2.3g/cm³, and high sphericity (≥0.9). These properties ensure excellent flowability and formability, suitable for SLM (Selective Laser Melting) 3D printing and MIM mass production of complex parts.

Oxygen Content Control: DH-S® technology excels in oxygen management, using a "one-control, two-reduction" approach to maintain fine powder oxygen levels at 1,500-1,800 ppm. The "one-control" aspect involvesKyhe's proprietary grinding process, which minimizes oxygen increase during spheroidization while maintaining near-spherical (≥90%) powder. The "two-reduction" step further lowers oxygen content for clients with stricter requirements.

Kyhealso offers "one-stop services," from powder development (in-house R&D, custom alloy formulations) and feedstock design to small-batch product validation. This comprehensive support streamlines manufacturing needs and provides tailored solutions, significantly shortening R&D cycles.

Certifications and Capacity:Kyhe's Dual Guarantees

Backed by Hard Strengths

Kyheleads the industry in sustainability certifications and production capabilities. Beyond GRS 4.0, its facility is Intertek-certified, covering mechanical recycling, molding, manufacturing, and non-final product storage/distribution. This ensures every step—from raw material recovery to powder production and finished goods—meets global standards.

Conclusion: The Future of Recycled Titanium Alloy Through the "Apple Effect"

Apple's 3D-printed recycled titanium alloy watch mid-frame is like a "pebble tossed into a lake," creating waves across manufacturing. It signals that sustainability, lightweighting, and precision will define high-end production, with companies mastering "recycled materials + advanced processes" gaining prominence.

With DH-S® recycled titanium powder's cost, performance, and certification advantages,KyheTechnology not only provides premium materials for MIM and 3D printing but also champions green manufacturing in line with global sustainability goals. In the race toward eco-friendly production,Kyhehas taken a solid step forward—and its future innovations in recycled titanium alloys are worth watching.