A fage kan elektronik na kula da abokan cin kayan zaman lafiya, kowane canje-canje na teknolojin Apple ya haɗa da kyau ga al'adun supply chain. A nufrin 10, 2025, sabin Apple na sabon Apple Watch Ultra 3, ya bada mid-frame na titanium da ke iya ƙaruwa wanda aka yi shi ta hanyar 3D-printing, yayin da ya kawo farin ciki ga sadarwa ta hanyar “na gona + inganci”. Wannan aiki ya sa “abubuwan hausa na titanium da ke iya ƙaruwa” da “tsinkin teknolojin 3D printing” su zama agogin sabon zaman lafiya.

Kyhe Takamunan da ke da nasarar tattalin arziki ta hanyar DH-S® (Dehydrogenation Spheroidal), wanda ke da takamunan abubuwan hausa na titanium da ke iya ƙaruwa da kuma halittaya Kyhe yasowa a ƙoma'ayin 3C na elektronik, tasho, da otomotika, wato yin amfani da kayan dabbobi na MIM (Metal Injection Molding) da tsarin nashirin 3D ta hanyar “kuduren gida + inganci mai kyau”.

Ma'aluma na Apple na "Alliage na Titanium Mai Amfani Daya"

Gimarwa Tsarin Faburka Ya Zama Abin Da Ake Buƙatar

Zaɓi na Apple na tsinkin titanium da aka yi daga sarari don mid-frame na sa’o’a, bai shine hanya ta musamman kawai ba ne mai nufin rashin amfani da abubuwan da ke bayanin tattalin arziki amma amsawa mai zurfi zuwa abubuwan tattalin arziki na zamani. Tsinkin titanium, wanda a known shi ne da wuyaƙe, tsaro mai zurfi, da kuma dole mai zurfi, yau da kullum shine abubuwan samawa mai zurfi ga samar da abubuwan mai zurfi. Amma, samar da tsinkin titanium ta hanyar zaman kansu yana da masira mai zurfi, kusurwar biyan kuɗi, da kuma zonayen kayayyaki. Aikin "samar da sabin + samar da 3D" yana kare da abubuwan samawa masu zinzamawa yayin da yake ba da damar samar da abubuwan da ke da tsaro mai kompliketitshin ta hanyar samar da abubuwan additively—wato yana daidai da manhajar Apple don karbon mitallaci har zuwa 2030 kuma abubuwan samawa mai wuyaƙe.

Daga wanne, wuri cikin irin wannan ayyukan da kuma inganciyan alama sabon kayan a cikin masu zuwa na hanyoyin amfani da furo. Ga kayan titanium na yau da kullun, DH-S® ya kuma karkatar da yawa daga cikin batutu da kuma halayyoyin yayin da ke nuna buƙatun maye da zama ban tsauri da ban gargaɗi ta hanyar amfani da tadinta addatu.

Don haka, tadinta mai zurfi na musamman zai dole ne ya yi la'akari da buƙatar aiki kuma ya nuna ilimin iyaka mai zurfi. Kyhe Teknoloji ta sami karfin da aka fi girmama a duniya GLOBAL RECYCLED STANDARD 4.0 (GRS 4.0) (Lamban Sertifike: ITS-TE-00126705-GRS-02566800). Kayan uku waƙa, DH-S® eco-friendly recycled titanium alloy powder, ana nuna shi sosai kamar "100% Recycled Post-Consumer Metal (Titanium Alloy)," don tabbatar da iko da saurin daidaitawa daga bishin kayan aikin. Wannan yana da alaƙa sosai da al'ammar tushen Apple, sannan Kyhe mai iyaka mai zurfi ga buƙatar kayan aikin mai zurfi.

Ƙwayar DH-S® na Titanium na KyheTech

Ayyukan Gudanar da Abubuwan Da Suke Kama Da Ƙwayar Rawar Titanium

A matsayin shagon teknoloji mai tsada ƙwayar titanium mai zurfi, Kyhe yana da quwatun tsarin sakaƙe na DH-S® na kimaɗi mai sakaƙe. Wannan abincin baruwa bai sauke shi ga yawan amfanin na'ura ko gaskiya a ƙirƙirar ƙwayar titanium ta hanyar zaman kansu ba, sai dai yana kuma karkatar da wasu abubuwan muhimmi: kuduren kudi da mahimmancin.

1. Tabbatar da Kuduren: Karfin Stainless Steel, Kuware da Ila'in Alloy na Titanium

A cewar zaman, "kuduren yawa" ita ce babban batun da take daki aikin zama zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuwa zuوا Kyhe 's takamaiman teknolojin DH-S® ya bada damar ƙirƙirar ƙwayar alloy na titanium daga kayan aikin da aka ambata, kamar ƙwayar mafi girman 53 microns, sharuɗɗan CNC na titanium, da sponge titanium. Ta hanyar wariskar batutuwan kayan aikin, Kyhe yana buƙatar sauraran kayayyaki, taimakawa wajen "ingantacciyar kalma a kudin guda". Waɗannan ragewar saura yana nufi cewa bayanan da ba su iya amfani da titanium saboda masallaci zai iya amfani da abubuwan maimakon masa na hannu da inganci, kuma yana bada damar samun alloy na titanium ga kowa. Misali, amfani da Kyhe titanium powder na sauƙaƙe na 3D ko tsarin MIM na mid-frame na watch na Apple yana taimakawa wajen dawo karfin aiki har ma an kula da sauran, kuma yana bada hanyar sabon mai iya amfani da "saurar sai" ga wasanin samar da kayan aikin mutum.

2. Range na Size na Particle na iya canzawa, kapasiti har zuwa 500 Tons

Tsarin EIGA na yau da kullum yana produce wani powder mai tsibirin girma alama ta hanyar normal curve, inda kawai 10% na kowane batch zai samu girman 0-20 micron (suitable for MIM) kuma yau da kullum 40% zai samu girman 15-53 microns (ideal for 3D printing). Bayan haka, teknolojin DH-S® tare da wasanni waɗannan iyaka. Taba ta bada iko inganta girman alama ta hanyar batch, tare da nisar yawa na 92%, tamkarwa cikin kwalin kalmomin abokin ciniki. A kuma, Kyhe yana amfani da takalmin 9,500-square-meter mai zurfi kuma tunanin biyu sun kammala. Base on current client orders, yana karƙashin production, targetin output na annually na 500 tons.

3. Tashiyya zuwa buƙatar masallacin high-end: Compatible with MIM da 3D Printing

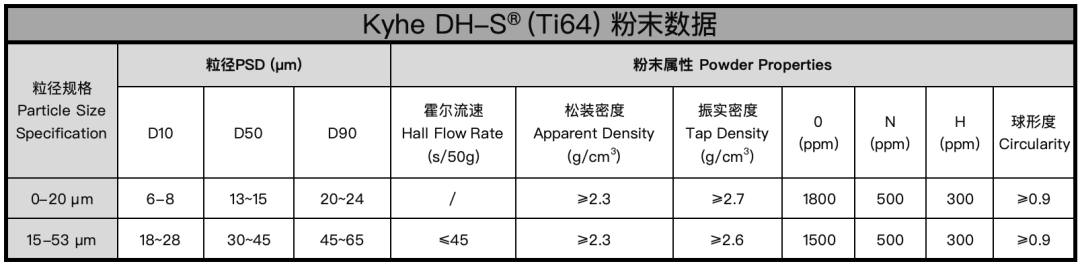

Kamar yadda aka gudanar da reduction na cost, Kyhe 's DH-S® titanium powder yana tsada performance. According to technical specifications, shi DH-S® Ti64 (Ti6Al4V) powder yana farfaru a cikin ma'anar mahimmanci:

Alaƙawar Na'illan: Tsarin kama'a ta 950 MPa, tsarin kama'a na yin aiki ta 850 MPa, zama mai tsada 15%, wanda ya tafi takamaiman ASTM F2885-11. Aikin sa ta hanyar kula da ruwa (gwaji na SST >240 sa’a) ya sa ya zama maimakon soyayya don ayyukan kalubale da abubuwan da aka hada da juyawa kamar kayan aikin kwayar mutum da kayan aikin tashin cikin mutum.

Alaƙawar Powdari: Kunna a cikin 0-20μm, 15-53μm, da sauran girman karami, tare da nau'in Hall na 20-50s/50g, girman daga baya ≥2.3g/cm³, da kyakkyawan gurbin (≥0.9). Waɗannan alaƙawar suna kirkirar iyaka mai zurfi da iko, wanda ke kama da SLM (Selective Laser Melting) 3D printing da MIM masoyin production na kayan da kayan aikin masu muhimmanci.

Kontin Kulu da Oksujin: Teknolojin DH-S® tana mamaki cikin kula da oksujin, ta amfani da "mai sauƙi, biyu an kara" don kirtar girman powdari mai oksujin a 1,500-1,800 ppm. "Mai sauƙi" yana iya Kyhe 'yan tsarin gurji, wanda ke kare maiƙar zuwa na oksijin lokacin spheroidization yayin da yake mai nishon kwayar (≥90%) dadin. Samfuri "biyu" ta zurfi kuma ke kare maiƙar oksijin don abokan ciniki da ke da buƙatar tarihi.

Kyhealso o yange "kayan aiki mai kungiya",daga samun dadin (R&D a cikin wasa, saduran alloy) da designin feedstock zuwa tabbatar da kayan aiki na karami. Wannan kankanta mai kungiyata ke sauya buƙatar fabrikatsi da kyauta hanyoyin halitta, wanda ke kare R&D cycles sosai.

Shahada da Sauran: Kyhe's Dual Guarantees

An tsiba ta Hard Strengths

Kyhe ya gabata kasuwar da shahadadar sustainability da alamar fabrikatsi. Bayan GRS 4.0, fasilitar saiye saiye Intertek, wanda ke kuskuren gyara mechanical, sadura, fabrikatsi, da maganar / fayilin bayan kayan aiki. Wannan ke kirkirce cikin kowane inganci—daga sauƙin ganin raw material zuwa samun daddin da kayan aiki masu iya amfani—ke daidai da standardun duniya.

Kammalawa: Amincewar Allo Na Titanium Mai Daukewa Ta Hanyar "Apple Effect"

Allo na Apple mai daukewa wanda aka 3D-printed daga titanium ya zama kamar "gurji mai ruwa" wanda yake fito a fagen takowa. Yana nuna cewa zaike da mahimmanci, sauƙi, da saukin aiki zai shahara a tsarin amfani da kayan aikin mai inganci, tare da sharuɗɗan da ke daidaita "kayan dauke + tsarin ci gaba" sun sami alaƙa.

Tare da abubuwan maimakon biyan kuɗi, aiki, da tasiri na powder DH-S® mai dauke Kyhe Teknoloji ba hanya ta bamu kayan aikin mai inganci don MIM da 3D printing ba, amma takaingila aikin amfani da kayan dauke wanda yake daidaita ma'aunin duniya na sustainability. A cikin rayuwa zuwa aikin amfani da kayan dauke, Kyhe ya kai koran gajere—kuma abokan saduwa na masa a cikin allo na titanium mai dauke suna da muhimanci.